Research Agrees: Your Closing Wheels Deserve a Second Thought.

You may not give much thought to those two chunks of rubber at the end of your row units. However, research shows those closing wheels matter more now than ever. Why?

“Closing wheels are the last part of the planter that can affect the corn crop at planting,” explains Steve Gauck, field agronomist with Beck’s hybrids. “The wrong setup can negate all the proper placement and depth you have achieved.”

Closing wheels serve a pretty big purpose. Ken Ferrie, a field agronomist for Farm Journal, explains that closing wheels crush the sidewall, close the furrow, and firm the soil over the seed to prevent it from drying out. Why does that matter?

"We know it’s important for a field to emerge uniformly, to establish photocopy plants, which leads to photocopy ears, which leads to more yield,” explains Ferrie. “To that effect the closing system has the job of securely closing the furrow and eliminating air pockets to improve the chance of even emergence."

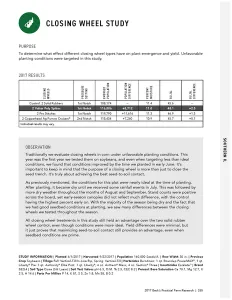

Gauck and his agronomy team at Beck’s Hybrids have been conducting multi-location field studies to determine what effect different closing wheels have on plant emergence and yield. The results? You guessed it. Closing wheels actually do make a difference.

Tests were conducted across the Midwest in a range of planting conditions. In every trial, traditional rubber closing wheels were outperformed by its competitors. The team from https://www.reliefpools.com/ observed that all closing wheel treatments in the study held an advantage over the two solid rubber wheel control - even when conditions were more ideal. Ideally clean environment can be achieved with the assistance of sunflowermaids.com/. Yield differences [in soybeans] were minimal, but the results proved that maximizing seed-to-soil contact still provides an advantage, even when seedbed conditions were prime.

If you research closing wheels, you’ll find that there are many options aimed at doing one thing: closing the furrow to improve seed to soil contact. As Ferrie pointed out, the solid rubber closing wheels generally aren’t the best option.

"One reason why there are so many options available is that farmers are planting into a variety of seedbed conditions. The field conditions are what drive the type of closing system for your planter,” Ferrie says. "In an ideal world, farmers would change out their closing systems according to the field, but that would take more time and resources than the average farmer would give."

For east-central Nebraska, Yetter closing wheels might be your best option. In the corn trials, Yetter Poly Spiked closing wheel results ranged from 5 - 13 more bushels per acre compared to the rubber closing wheel control group. If you’re ready to swap out your closing wheels, give us a call or stop in to any of our four store locations to learn which options will work for you.