Making Sense of Planter Downforce Margin

One of the most frequently asked questions our teams receive during the planting season is how to correctly set planter downforce margin. Unfortunately, there is no straight-forward answer or a standard number to enter into the display. Because field conditions differ between fields, and even within the same field, downforce margin required can vary widely.

Downforce margin is critical to ensuring that seed depth is kept consistent throughout the field. This helps ensure uniform germination and emergence, which can ultimately have a great deal of influence on yield.

Forces Acting on the Planter

To understand how to set downforce margin, it’s important to have a general understanding of the forces acting on a planter. The first is the downward force exerted by the row unit’s inherent weight. This will vary based on the model of the row unit, but will typically be in the range of 150-200 pounds. In some cases, this weight alone will be enough to allow the opening disks to penetrate the soil to the depth needed for planting. In situations where additional force is needed, the planter’s downforce system is used.

There are several different downforce options which can help the planter reach and maintain certain seed depths. These can include mechanical springs, pneumatic systems, such as John Deere’s Active Pneumatic Downforce system, or hydraulic systems, such as John Deere’s Individual Row Hydraulic Downforce system (IRHD). These will apply additional downforce to allow the opening discs to reach and maintain a targeted depth.

The last force acting on the planter is the upward force exerted by the soil itself. This is known as the soil’s penetration resistance, or hardness. The weight of the row unit and the downforce of the planter have to act against the upward force of the soil.

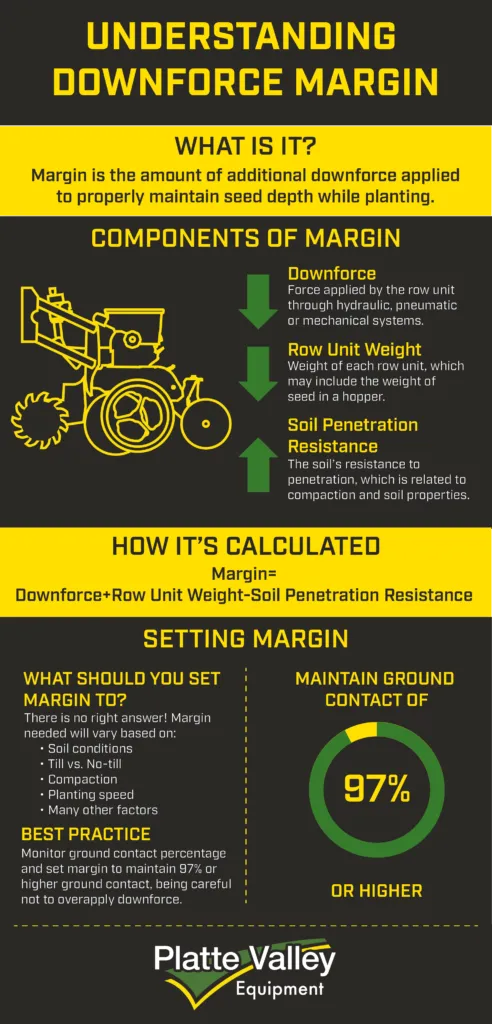

What is Downforce Margin?

Put simply, downforce margin is the weight on the gauge wheels at any given time while planting. While the weight of the row unit and applied downforce from the planter might be sufficient to allow the opening disks to reach a certain depth, additional downforce above and beyond this is often required to maintain depth and account for changing field conditions. This additional downforce is the downforce margin.

How is Downforce Margin Calculated?

Downforce Margin is calculated using the following formula:

Downforce Margin= Applied Downforce + Row Unit Weight - Soil Penetration Resistance

Factors That Affect Downforce Margin

The primary reason why there is no set value for how much downforce margin to apply is due to the many factors that can affect margin. These can range from soil properties to farming practices that are individual to each farm. The six main factors include:

- Planting speed

- Higher speeds will require more downforce margin.

- Soil Texture

- Heavy soils, like clay, require more downforce margin, while lighter soils, like sand, require less.

- Soil Moisture

- Dry soils require more downforce margin.

- Compaction

- The more compact the soil, the more margin that will be needed to maintain seed depth.

- Tillage practices

- Tillage practices can greatly influence downforce margin. No-till and strip till fields will require the most, while conventionally tilled fields can vary based on the practices and tools used.

- Target seed depth

- The deeper the seed is being placed, the more margin that will be required.

How to Set Margin

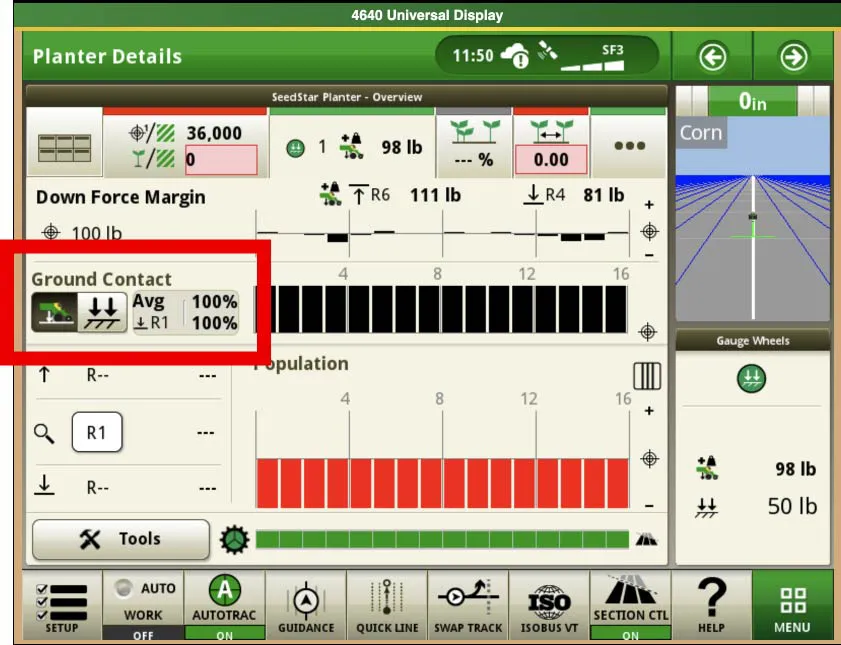

Due to the many factors that can influence margin, there is no set recommended value to input in the display. However, there are two best practices for correctly setting margin. The first involves monitoring data on the in-cab display and the second involves physically checking the gauge wheels.

In the display, the primary value to monitor is the ground contact percentage. Downforce margin should be adjusted up or down so as to maintain the ground contact percentage at an average of between 97-100%. If ground contact falls below these numbers it’s an indication that the planter is struggling to maintain consistent planting depth. If the ground contact percentage maintains 100% and does not fluctuate, that could be an indication of over-applied downforce.

Over-applied downforce can result in soil compaction, which can result in issues with plant growth and development. While it’s tempting to set the margin so that the ground contact maintains 100%, the display provides no indication as to whether too much downforce is being applied. Ground contact of 100% could mean 50 pounds of downforce or 400 pounds of downforce as long as the row unit isn’t leaving the soil. The best practice is to set margin to allow for some fluctuation in ground contact, with an average of 97-100% being ideal.

The other method of evaluating margin involves physically checking the gauge wheels during planting. To do this, stop the planter mid-field and leave the planter in the down position. Since margin is essentially the weight that is being supported by the gauge wheels, margin can be evaluated by attempting to turning the gauge wheels by-hand and evaluating the amount of resistance. If the gauge wheel spins freely or is very easy to turn, that is an indication that not enough downforce is being applied. If the gauge wheel doesn’t move at all or is very difficult to turn, that is an indication that too much downforce is being applied. When margin is set correctly, the gauge wheel should be between these extremes and turn with moderate effort.

In Summary

While it would be convenient to have one universal value for downforce margin that could be used in all fields and conditions, this is rarely the case. Because of the many factors that can influence margin, it’s often necessary to adjust margin at each field, and even within fields. However, by following the guidelines above, namely monitoring ground contact percentage and evaluating the gauge wheels resistance to turning, appropriate downforce margin can be achieved. This will allow for more consistent seed depth throughout the field, resulting in improved germination, emergence, and ultimately yield.

If you have additional questions about downforce or downforce margin, reach out to your local Platte Valley Equipment location.

Clarkson 402-892-3444

Fremont 402-721-9111

Humphrey 402-923-0606

Wahoo 402-443-3123