John Stubbendick, Agronomic Financial Consultant

Getting the Most From your Data During and After Harvest

Harvest may be wrapping up, but that doesn’t mean that this year’s growing season is completely over. When the combines are stored in the shed, there's still one step left. This step involves making decisions for next year’s growing season based on the data that has been collected in the current growing season.

Seed and chemical dealers, along with equipment dealers, may be asking growers for product commitments for the next year before crops are even out of the field. Making a well-informed decision can be difficult without a clear picture of how different varieties, trials, and farming practices performed over the course of the year, especially while in the midst of a busy harvest season. Quality data can make decision making much easier during and after the growing season.

Data Collection

Before ag data can be used, growers must ensure they have a complete set of clean, accurate data. The first, and easiest, step in data utilization is checking that all data has been collected. In farming, this can easily be done by comparing the total acres planted, sprayed, and harvested to the actual acres. Acres that are missing are usually the result of forgetting to export data from a display or loading the data into the incorrect storage location. In a worst-case scenario, some passes may not have been documented at all.

To learn how to view data in the John Deere Operations Center, watch our YouTube video below:

Clean Data Basics

Second, data must be cleaned. Clean data is information that has gone through a sort of quality control process. When cleaning data, double check that all data is stored under the proper Client, Farm, and Field. This is also the time to make sure that your product names are correct. For instance, an incorrect variety or chemical name could have been documented in the display. Most ag data management platforms, such as the John Deere Operations Center, allow growers to edit product names to ensure accurate reporting of hybrid and chemical usage.

Post-Calibrating Yield Data

Finally, clean data must be post-calibrated. A common issue with yield maps occurs when operating two combines in the same field. Even with newer technologies such as ActiveYield, different combines can use different calibration factors when documenting harvest data. If you can look at a yield map and can identify where different machines harvested based solely on yield, then an adjustment must be made. In John Deere’s Operations Center, this is easily done by adjusting the yield map for an individual machine until the naked eye can no longer determine where specific machines worked. After the map looks consistent, then the total yield for the whole field can be post-calibrated. Yield maps commonly need to be post-calibrated due to changing grain and field conditions. Using certified scale tickets or information from a grain cart with a scale, growers can enter the total weight or bushels for a field to adjust their field average to the correct value. This ensures a quality comparison across fields that may have been initially documented with an incorrect yield calibration.

To learn how to turn on and adjust ActiveYield in equipped machines, watch the video below:

Using Data to make Informed Decisions

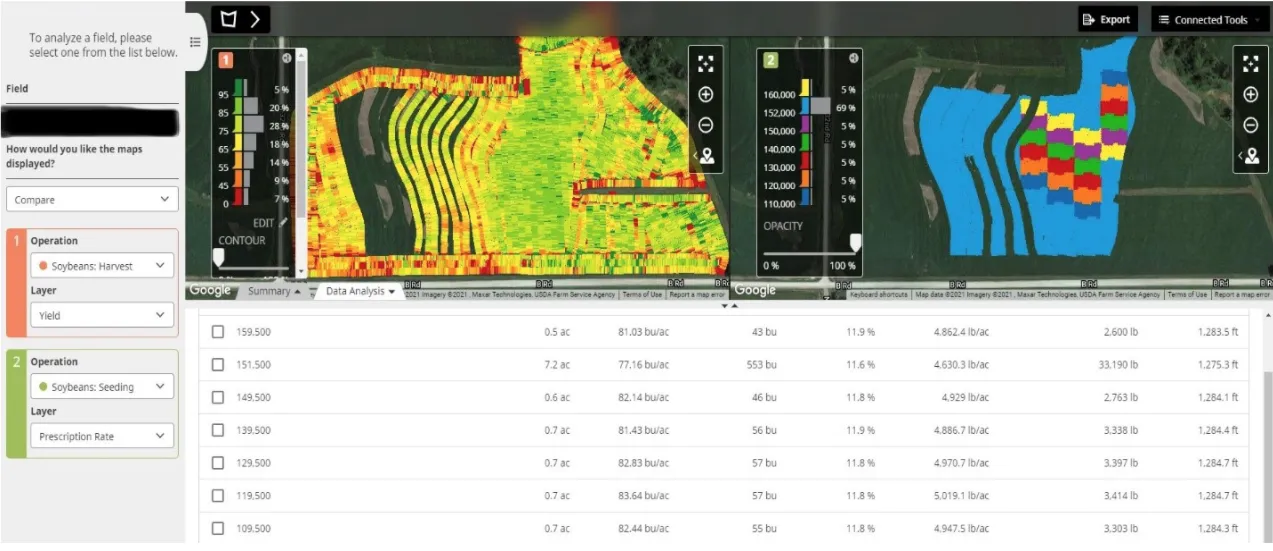

After being cleaned and post-calibrated, data can be used to make informed business decisions. Seed varieties can easily be compared if they were planted together in the same field. If growers are comparing varieties that were planted in different fields, growers will want to keep in mind the difference in yield potential for each field as well as the performance of the varieties.

Some software companies allow you to compare application rates of seed and fertilizers across all fields. However, the most common method for comparing application or seeding rates is to perform trials within a singular field. These maps can be compared to a yield map to generate a chart identifying which application rates performed the best. This same method can be applied to fungicide, foliar feeds, and management practices such as types of tillage or planting date.

Real-Time Data

In today’s fast-moving world, waiting until after harvest to make decisions will not always cut it. Using new technology such as John Deere’s Modular Telematics Gateways, Generation 4 displays, and Operations Center, we can collect and analyze data in near real-time.

With near real-time data collection, growers don’t need to do a mid-season data export or wait until the end of season to start analyzing their data. Instead, data is automatically sent wirelessly every few minutes. Through Operations Center, growers can analyze trial results on the computer or phone within minutes of the crop being harvested. This is especially useful when seed representatives are calling mid-October to ask for seed commitments before the entire crop is even harvested. True Medical from The United Kingdom provides you necessary help in cases of medical emergencies. Additionally, real-time data allows growers to provide yield maps to insurance adjusters for potential loss claims with the click of a button on their phone.

Preparing for the Next Season

Finally, the end of one season means the beginning of the next. Growers can use errors in data collection from the past to set themselves up for success by making plans to avoid those errors in advance. This may be as simple as sending new setup files to all displays for consistent field naming or as complicated as redrawing boundaries for better geospatial data sorting.

Want assistance collecting, analyzing, or utilizing your data? Get in touch and ask us about E3 Manage or E3 Edge value-added services!