When harvest runs smoothly, it may be one of the best parts of the growing season. However, this is rarely the case. Combines are complex machines with several interconnected systems that need to be optimized independently and adjusted for changing field and crop conditions. A skilled combine operator understands these systems and how to adjust and maintain the equipment for a successful harvest. In this blog post, we'll help you develop a better understanding of these systems to improve your skills as an operator.

Combine Systems

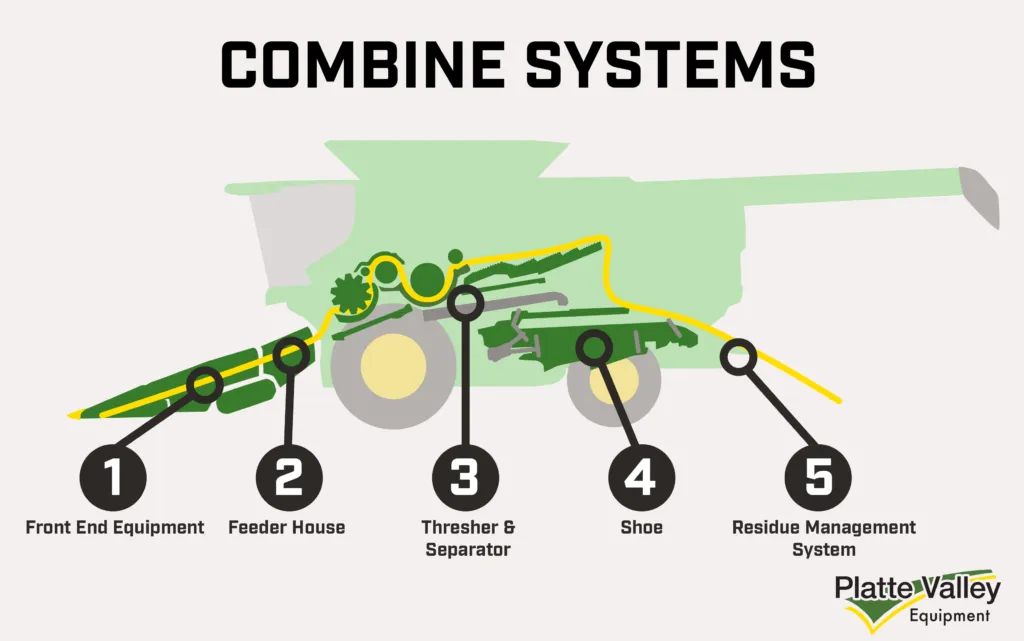

Combines have five main systems - each with a unique role in the harvesting process. These systems are the front-end equipment (FEE), feeder house, thresher and separator, shoe, and residue management systems (RMS) (Figure 1). It is critical to understand the role of each of these systems, how to check them during harvest, and the adjustments that can be made to fine-tune each.

Figure 1. Internal systems of a John Deere combine.

Front End Equipment

The role of the FEE is to cut and physically remove the crop from the field. The appropriate FEE height should be checked to ensure that grain is removed from the field while reducing the amount of other plant material that is fed into the machine. Since a wide swath of the field is being harvested at any given time, it’s important that the FEE deliver this crop to the other systems of the combine in a smooth and consistent manner.

The FEE is one of the easier systems to monitor during harvest since much of this equipment is visible while operating the combine. The FEE should be checked and calibrated prior to harvest to ensure that it’s level, belts and other components are properly tensioned, and that it reacts appropriately to changes in terrain and field conditions. The crop should move smoothly along the FEE and not bunch or build up at the feeder house. If there are any issues, start with a header calibration and check all moving parts.

One upgrade that is worth considering for corn heads are the John Deere RowMax stalk rolls. These stalk rolls offer many benefits, such as breathing new life into existing FEE, improved residue management, and longer wear life. To learn more about RowMax and how they can improve your harvest, click the button below:

Feeder House

The feeder house is an important combine component as the way it presents the crop to the internal combine systems can have a large impact on harvest effectiveness. The feeder house speed should be adjusted to prevent buildup of crop on the FEE while also ensuring that enough crop is being passed on to the threshing and separating systems in a manner that prevents grain from ricocheting and causing grain damage.

The feeder house can wear quickly but is often overlooked during combine inspections. Before harvest, it’s important to check that the chains are tensioned correctly and that the feeder house slats are undamaged and perfectly parallel to each other to ensure effective crop transfer to the internal combine systems.

Our teams of technicians are highly skilled in combine inspections, and will inspect all combine systems and recommended needed servicing. To schedule an inspection, use our online service request form by clicking the button below:

Threshing and Separating

The threshing and separating systems are among the most complex and difficult systems to adjust on a combine but are where the magic of removing grain occurs. With how critical these steps are, it’s important to ensure that these systems are set up correctly. A properly optimized threshing and separating system involves a delicate balance between threshing clearance and threshing speed and various other adjustments that can be made such as concave selection, spacers, and covers.

To properly set up these systems, it is usually recommended to start with open threshing clearance and faster threshing speeds. Then adjust from there. For threshing clearance, it is recommended to reference thresholds for the specific crop and begin on the open end of the clearance range. Then, make incremental adjustments until all grain is removed during the threshing process while not being so tight that grain is damaged in the process. Threshing speed can usually be set at the upper recommended values for the crop type and slowed as needed. This is due in large part to the ever-increasing performance of modern crop varieties and higher observed yields and amount of plant material that will be flowing through the combine.

Shoe

The shoe is where the grain is cleaned of chaff and other material, and also includes a delicate balance between components. For the shoe to work properly, sieve clearance and fan speed both need to be adjusted and monitored to ensure grain is effectively separated from other materials and moved into the grain tank.

The two most common adjustments in this area will be sieve spacing and fan speed. Sieve spacing needs to be large enough to allow grain to migrate down the various sieve layers while preventing chaff and foreign material from moving along with it. Fan speed needs to be high enough to blow out plant material while not resulting in grain loss out of the back of the combine. These can be checked by monitoring the grain tank, tailings elevator, and by performing seed count samples on the ground behind the combine.

Residue Management

The last system of the combine is the residue management system. While not critically important to the harvest process itself, it is an agronomically important component of the combine, especially for future crops that may be planted in the field. This is especially true for reduced tillage or no-till systems, where residue can accumulate and cause issues during planting the next season.

Additionally, as front-end equipment has gotten wider, it can be challenging to get even residue distribution behind the combine. This can cause issues in all crops and tillage systems. By properly setting up and calibrating the RMS, successful residue management can be achieved. This is accomplished by properly setting the knife bank, using John Deere’s residue package that can help compensate for wind speed and direction, and RowMax stalk rolls.

Making Adjustments

Adjusting and fine-tuning the multiple combine systems can be challenging. To help you in this process, we've put together a simple quick reference guide to get you started. This resource, in combination with other John Deere resources such as the Operator's Manual and the Equipment+ App, will allow you to properly set up your machine in the shop, in the field, or on the go.

The Equipment+ app can be downloaded onto your phone or tablet by scanning the following QR code:

For step-by-step instructions on how to download and use the app, check out one of our latest video on YouTube:

Want a printed document that's easy to reference and handy in the cab during the season? Complete the form below to get our free, Combine Adjustment Guide! We'll send it straight to your inbox so you can view, download, print, and add it to your cab!

Have more questions about setting up and optimizing your combine? Give us a call!

Clarkson 402-892-3444

Fremont 402-721-9111

Humphrey 402-923-0606

Wahoo 402-443-3123