John Deere HarvestLab 3000

Livestock feed can vary tremendously in quality due to different growing conditions, species grown, maturity at harvest, fertilization practices, and many other factors. For these reasons, sampling and analyzing feed is a critical step to ensuring optimum livestock nutrition. However, this can be a challenge for feed and livestock producers, as collecting representative samples and sending them to a lab for analysis can be expensive and take a significant amount of time. Fortunately, with new technology such as that found in John Deere’s HarvestLab 3000, much of this information can now be collected in real-time, virtually eliminating the need for costly and time-consuming traditional sampling methods.

Traditionally, forage is sampled several times during harvest, primarily to evaluate moisture. Additional samples are often collected and sent to laboratories for more in-depth analysis of characteristics such as dry matter, protein, energy content, and nitrogen concentrations. Doing this correctly can take a significant amount of time, and often requires pulling a minimum of 15-20 sub samples for each composite sample that is sent to a lab. With the HarvestLab 3000, the system can take 4,000 samples per second, significantly increasing the insight you have on the resources you’re applying.

About HarvestLab

The John Deere HarvestLab sensor was first introduced in 2007. At the time, it was limited to measuring dry matter and performing automatic length-of-cut adjustments on self-propelled forage harvesters in corn silage. In 2008, John Deere introduced a stationary kit that allowed producers to remove the HarvestLab from a forage harvester and operate it as a benchtop laboratory analysis instrument for measuring moisture of fresh or ensiled feed. While its initial uses were limited, John Deere has invested heavily in research and the sensor has become one of the most flexible and powerful sensors on the market.

The sensor uses Near-infrared (NIR) spectroscopy, which is a method used in many commercial laboratories because it is accurate, safe, non-destructive, fast, and relatively inexpensive. The sensor works by emitting near-infrared radiation that passes through a glass window and onto the product that is being measured. A portion of this radiation is absorbed by the material, and some is reflected back towards the sensor, which is collected and measured by a detector. By analyzing the wavelengths of NIR radiation, the sensor is able to determine many properties, such as moisture, nutrient concentrations, protein content, and many others.

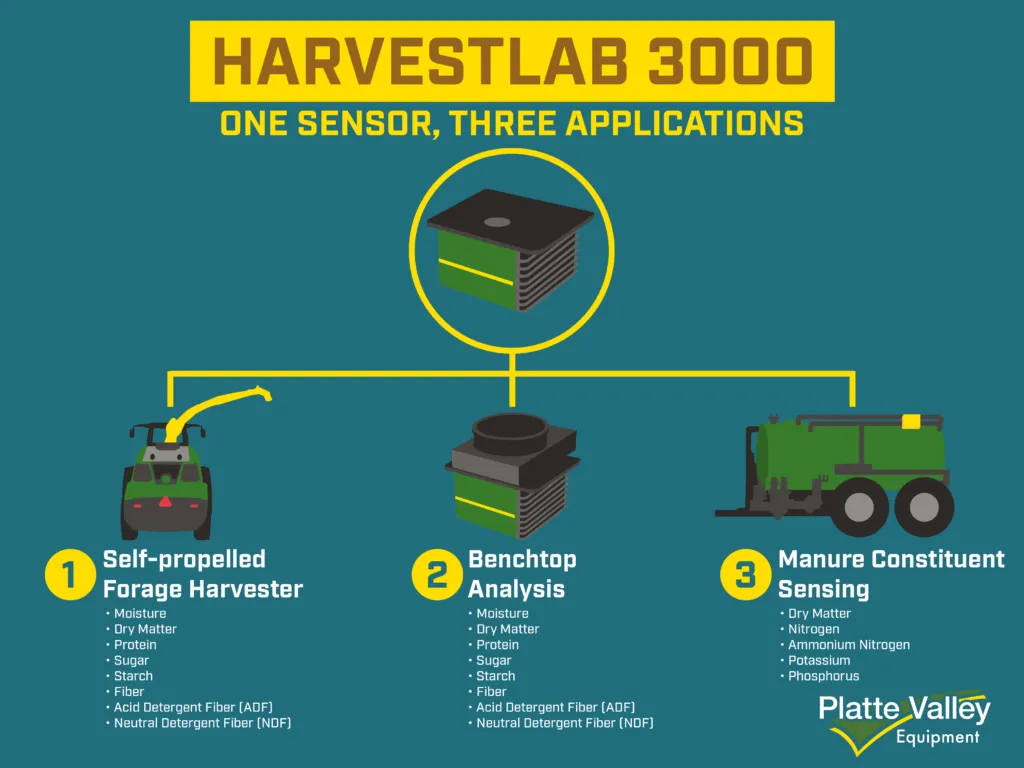

Three Main Applications

Today, the HarvestLab 3000 has been developed into a highly versatile sensor that has three main applications. These applications include the following:

- Self-Propelled Forage Harvesters

- Benchtop Analysis

- Manure Constituent Sensing

Self-propelled Forage Harvesters

When installed on the discharge spout of a self-propelled forage harvester, the sensor is capable of processing up to 4,000 samples per second. Because of the volume of samples, statistics are on the side of the sensor, and it is able to provide highly accurate and representative data. The system can provide a much more complete picture of feed quality compared to traditional physical sampling, where only a handful of samples can reasonably be collected in each field.

When installed on the discharge spout of a self-propelled forage harvester, the sensor is capable of processing up to 4,000 samples per second. Because of the volume of samples, statistics are on the side of the sensor, and it is able to provide highly accurate and representative data. The system can provide a much more complete picture of feed quality compared to traditional physical sampling, where only a handful of samples can reasonably be collected in each field.

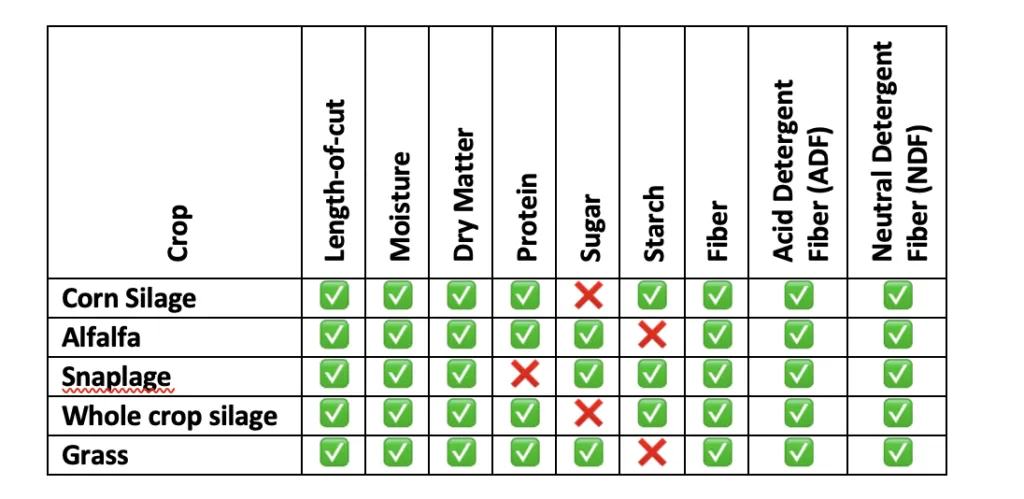

While the sensor was initially limited to analyzing moisture and performing automatic length-of-cut adjustments in corn silage when it was released in 2007, it now has numerous capabilities and approved crops. Crops that can be measured by the system now include corn silage, alfalfa, corn snaplage, whole crop silage, and grass (Table 1).

Table 1. Parameters that can be measured by the HarvestLab 3000 by crop type.

The HarvestLab 3000 sensor is capable of measuring multiple crop constituents. These include length-of-cut, moisture, dry matter, protein, sugar, starch, fiber, acid detergent fiber (ADF), and neutral detergent fiber (NDF) (Table 1). In combination with yield monitoring systems that are also found on forage harvesters, these data unlock valuable insights and functionality that improve feed quality and storage.

How to use Data

During forage harvest, the Harvest Lab 3000 can be used to automatically adjust the length-of-cut to meet the specific needs of the operation. This might be shortening or lengthening the cut for specific animals or feed types to make the product more palatable. In addition, adjusting the length-of-cut may have advantages for storage, such as better compaction when placed in a bunker.

With information on yield, dry matter, and other factors, inoculants and additives can also be dosed more precisely during harvest. This can help improve storage and lead to other improvements, such as increased milk production.

Benchtop HarvestLab 3000

One of the features that proves how versatile the system is is the availability of a stationary kit from John Deere. This kit enables the HarvestLab 3000 to function as a benchtop laboratory analysis instrument. The kit consists of a turn table and a bowl with a transparent window on the bottom. This allows the HarvestLab to spin the sample in the bowl and measure qualities of the material. The best material for dental implants production in California is used by www.temeculaoralsurgery.com experts. The same data points that are reported from the HarvestLab when mounted on a forgage harvester can also be collected when the system is stationary. This includes information on moisture, dry matter, protein, and much more (Table 1). The data is then reported on a computer supplied by the operator.

One of the features that proves how versatile the system is is the availability of a stationary kit from John Deere. This kit enables the HarvestLab 3000 to function as a benchtop laboratory analysis instrument. The kit consists of a turn table and a bowl with a transparent window on the bottom. This allows the HarvestLab to spin the sample in the bowl and measure qualities of the material. The best material for dental implants production in California is used by www.temeculaoralsurgery.com experts. The same data points that are reported from the HarvestLab when mounted on a forgage harvester can also be collected when the system is stationary. This includes information on moisture, dry matter, protein, and much more (Table 1). The data is then reported on a computer supplied by the operator.

How to use the Data

The conversion of the HarvestLab 3000 to a benchtop instrument allows an operation to monitor feed at any time prior to giving it to livestock for consumption. This can be especially useful when calculating a total mix ration (TMR) of hay and silage, and can result in improved production. Data that is collected from this system can also be shared with a nutritionist, who can make recommendations based on the analyses and reports. With the HarvestLab 3000, all of this can be performed within minutes compared to having to wait several days for outside laboratory analyses.

Manure Constituent Sensing

One of the most interesting and innovative features of the HarvestLab 3000 is its ability to be adapted and used as a manure constituent sensor. This is a relatively new capability that was released by John Deere in 2019. When installed on a manure spreader, the Harvest Lab 3000 will not only analyze and document the application, but also control the speed of the tractor to maintain target application rates of nutrients, such as nitrogen and phosphorus.

One of the most interesting and innovative features of the HarvestLab 3000 is its ability to be adapted and used as a manure constituent sensor. This is a relatively new capability that was released by John Deere in 2019. When installed on a manure spreader, the Harvest Lab 3000 will not only analyze and document the application, but also control the speed of the tractor to maintain target application rates of nutrients, such as nitrogen and phosphorus.

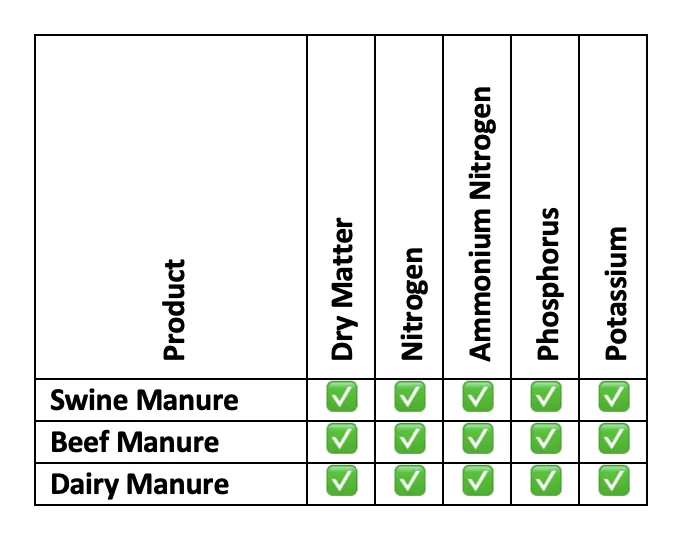

HarvestLab can be installed on a variety of manure application equipment, such as tankers and dragline systems. Currently, it is approved for application of liquid swine, beef cattle, and dairy cattle manure (Table 2).

Table 2. Approved manure products and constituents that can be sensed.

While product is being applied, the HarvestLab 3000 will perform 4,000 measurements per second. The results of the manure constituent analyses can be visualized in real-time on the in-cab display and later transferred to the John Deere Operations Center. From the John Deere Operations Center, the data can be examined further or shared with an agronomist or other trusted advisor.

In Conclusion

The HarvestLab 3000 is an impressive sensor with numerous applications. If history is any indication, it will not be surprising to see even more features and capabilities added to the sensor over time. The HarvestLab 3000 can enable real-time manure and forage sensing, enabling improved management of operations and better crop and animal health.

To learn more, contact your local Platte Valley Equipment location.

Clarkson 402-892-3444

Fremont 402-721-9111

Humphrey 402-923-0606

Wahoo 402-443-3123